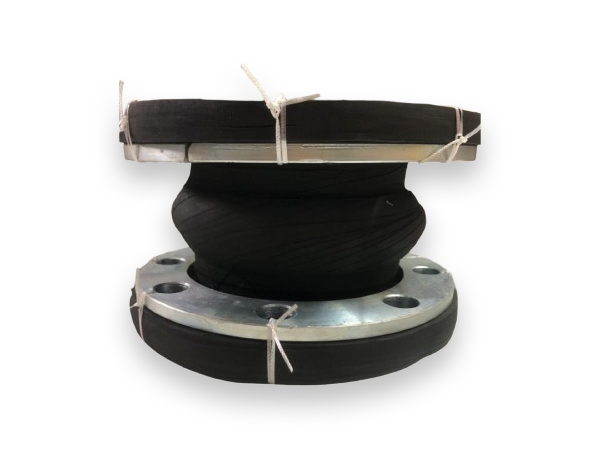

A rubber expansion joint is a flexible connector crafted from natural or synthetic elastomers and fabric, often reinforced with internal metallic rings. Its primary purpose is to act as a 'shock absorber' within piping systems, providing stress relief by absorbing thermal expansion, contraction, and mechanical vibrations. By allowing for axial, lateral, and angular movements, these joints prevent the buildup of stress that could otherwise lead to pipe deformation, flange breakage, or damage to sensitive equipment like pumps and compressors.

Beyond movement absorption, rubber expansion joints are highly valued for their ability to dampen noise and isolate vibrations, making them essential in HVAC systems, water treatment plants, and power generation facilities. Their non-metallic construction offers superior resistance to corrosion and abrasion compared to metal joints, which is particularly beneficial when handling slurries or aggressive chemicals. Because they are resilient and do not suffer from fatigue in the same way metals do, they provide a long-lasting, cost-effective solution for maintaining the structural integrity of industrial pipelines.

Discover the wide range of industries and applications where Rubber Expansion Joints delivers exceptional performance and reliability.

Used in water supply and sewage systems to absorb movement, vibrations or pressure surges thereby reducing stress on pipes.

Rubber expansion joints are used in heating, ventilation and air conditioning systems to absorb movements due the thermal expansion of pipes or ducts.

These are the rubber expansion joints applied in steam systems for control thermal expansion and relieve to some level stress on piping or fittings.